TECHNICAL TESTING & ANALYSIS

Start with the end in mind and design right with our technical testing and analysis

We help you understand & solve your packaging challenges

With our R&D capacity and capabilities, we can help your team get your packaging design right with the end in mind. Through our lab’s technical testing and analysis, you can design your packaging right from the get-go.

STRETCH HOOD

We will test your stretch hood performance in simulated wrap conditions. You will learn what suitable materials and optimum stretch percentage to use for proper sealing and load stability from the test.

STRETCH FILM

We will wrap test your stretch films on a turntable, arm or ring wrappers. You will know the optimal film, resolution, and stretch percentage you should use for the best load stability from the test.

SHRINK FILM

The shrink film or shrink wrap test ensures quality films are used. You will also learn the right heating level and time to apply for optimal shrinkage to secure your goods accordingly.

OUR OBJECTIVES

- To strive for creativity in our innovation with technological applications

- To explore innovative ways to solve freight challenges and problems

- To develop new and improved secondary and tertiary packaging materials

- To enhance our existing methodologies with the integration of new technologies

- To create results through our evidence-based findings and solutions

- To reduce the probability of product damages

- To increase the accountability of all parties

An accredited Research & Development Centre by MIDA

Newton is officially recognised by the Malaysian Investment Development Authority (MIDA) as a research and development centre. In believing that growth and innovation are infinite, we invest our resources in continuous research, analysis and development. We will continue to play the vital role of setting high safety standards and adhering to local and international security regulations.

With our R&D capacity and capabilities, we can help your team to get your design right with the end in mind. Through our lab’s technical testing and analysis, you can design your packaging right from the get-go.

SCOPE OF TESTING & SIMULATIONS

We test the performance of your stretch wrap film after applying it to your unit load. We do so by simulating your packaging line set up to perform the test.

Objective:

Optimise your stretch wrap applications through a proper selection of films, packaging machines and wrapping settings.

Test Scope:

- Total strain rate

- Thickness after strain

- Forces applied to the load

- Film’s puncture resistance

We test your stretch hood packaging performance by simulating your stretch hood packaging line and applying various conditioning based on your distribution environment.

Objective:

Optimise your stretch hood packaging and ensure your load is secured throughout your distribution environment.

Test Scope:

- Film conditions

- Film performance

- Elastic recovery

- Film edge force

We test your collation shrink film properties by applying differing conditioning using our shrink tunnel simulation.

Objective:

Optimise your collation shrink film properties, including appearance and holding properties.

Test Scope:

- Holding properties

- Shrinkage

- Tensile test

- Coefficient of friction

As an ISTA certified lab, we offer tests according to the protocol designed by ISTA. The test includes a range of simulations of transportation environments and motions from the distribution environment.

Objective:

Help you minimise product damage throughout your distribution and optimise your resource usage via test data for effective package design.

Test Scope:

- Environmental conditions

- Shock

- Vibration

- Compression

This transport simulation test is per EUMOS 40509 standard commonly used in Europe. We use our gravity force simulator to test one-way directional force emulating transportation during distribution.

Objective:

Help you determine your load stability through the performance of your packaging methods and optimise your pallet packing and stacking.

Test Scope:

- Acceleration threshold

- Deceleration threshold

- Wrapping methods

Stacking methods

The incline impact test is a shock simulation on packaged load, crucial for fragile products, and the results are used for packaging optimisation.

Objectives:

- To test horizontal shipping direction & handling in cargo or warehouse

- To reduce the risk of damage during the distribution cycles and arrive safely at the destination

The film performance test is used to test the properties of stretch film. It can simulate stretch wrap machines in the market with varying speeds to measure the stretch film consistency.

Objectives:

To perform the following at different constant speed

- Ultimate test

- Puncture test

- Relaxation test

- Cling test

- Tear propagation test

- Film consistency

The FEF test is done with portable devices that measure the wrapping force at the corner of palletised loads. It can be installed on any pallet before wrapping, even at the user’s site.

Objectives:

- To generate forces on the edge of the pallet during or after a wrapping process

- To analyse the wrapping performance of stretch film and stretch hood

The transportation simulation system tests your loads with accurate replication of load transit behaviour. It uses sustained tilt testing with vibration during the test.

Objectives:

- To monitor and record any displacement of palletised load

- To analyse the load stability and safety using a laser profile scanner

The bench test uses gravity force in mono direction, accelerate or decelerate, to simulate forces generated during transportation. This test is conducted according to EUMOS 40509 test standard, commonly used in Europe.

Objective:

To determine the performance of packaging method in transportation environment for road safety

The equipment for this test is a multi-axis simulation system simulating vertical vibrations and pitch and roll movements. The real-world distribution cycle conditions can be recorded and simulated at the dynamic lab for testing. The vertical vibration tests come in several standard compliances like ASTM, ISO and ISTA.

Objective:

To discover the impact of load handling during the distribution cycle on the packaging and product

The atmospheric conditioning test is a chamber that simulates an environment with controlled temperature and humidity on your palletised load.

Objective:

To discover the impact of different atmospheric conditions on the packages and product

The UV chamber test simulates the weathering effects on the material using UV light and water apparatus. The physical and mechanical properties of the packing materials will be tested with other devices after the UV conditioning.

Objective:

To test the impact of sunlight and moisture from rain exposure on the palletised load and products

This test analyses the resistance of packaging materials, full palletised load, carton boxes and products to the simulated compression of up to 5000 kg.

Objective:

To evaluate the impact of compression happen on loads during handling and stacking in cargo or warehouse

The rotary vibration system produces fixed-frequency vibration in rotary motion on your unit load, simulating the delivery of a parcel or product in transport.

Objective:

To determine the quality of product upon arrival at the destination

The random vibration system simulates the transport vibration environment through vertical vibration with power spectral density and frequency. In ASTM compliance standard, the mode of transport like a truck, rail and air vibration profile in different test duration is recommended.

Objective:

To determine the quality of product upon arrival after a specific transport environment

The package drop test is done by dropping packages from varying heights onto different surfaces, edges, corners or hazards. This test is necessary as we often get damaged containers or package products from delivery handlings.

Objective:

To ensure products are secured to withstand delivery handlings and arrival in good condition

Forklift handling comprises various simulation tests, such as a forklift handling course with an obstacle-designed track according to test standards.

Objective:

To forecast the quality of the packaging used in sustaining the rough handling of loading and unloading activities in the warehouse

The coefficient of friction test is used to examine the plastic film surface, namely material smoothness and more.

Objective:

To control and adjust the technical indexes for the quality of the material in meeting users’ application needs

The universal tensile test is used to test and compare the tensile strength, elongation and elasticity of plastic film properties. Our tests comply with a few international standards, such as ASTM D882.

Objective:

To examine the properties of plastic film for optimal application and wrapping settings

The dart impacts test measures and compares the impact resistance of plastic, sheets, and composite films. Our impact test is according to ASTM D1709 with the dart set at a specific height and free drop on the packaging materials.

Objective:

To evaluate the impact resistance of plastic packaging materials

The SPT is designed for testing shrink bundles packaging properties after shrinking. This is vital for shrink hooded pallet load stability. The shrink film properties tested include strength, elasticity and holding performance.

Objective:

To improve on the raw materials, extrusion process, shrink temperature, humidity and other tunnel parameters according to the result tested with secondary packaging tester

SCOPE OF TESTING & SIMULATIONS

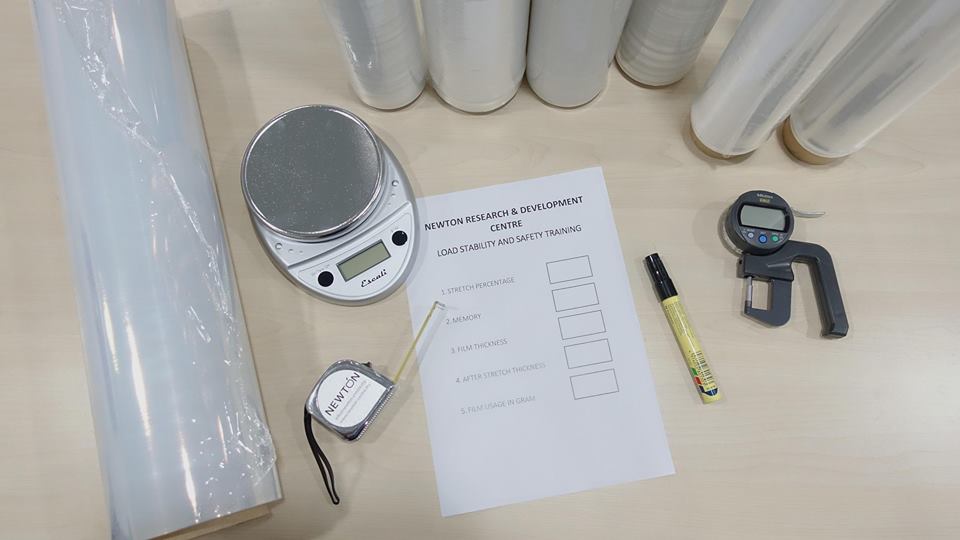

STRETCH FILM DIAGNOSTIC TEST

We test the performance of your stretch wrap film after applying it to your unit load. We do so by simulating your packaging line set up to perform the test.

Objective:

Optimise your stretch wrap applications through a proper selection of films, packaging machines and wrapping settings.

Test Scope:

- Total strain rate

- Thickness after strain

- Forces applied to the load

- Film’s puncture resistance

- More

STRETCH HOOD DIAGNOSTIC TEST

We test your stretch hood packaging performance by simulating your stretch hood packaging line and applying various conditioning based on your distribution environment.

Objective:

Optimise your stretch hood packaging and ensure your load is secured throughout your distribution environment.

Test Scope:

- Film conditions

- Film performance

- Elastic recovery

- Film edge force

- More

COLLATION SHRINK FILM TESTS

We test your collation shrink film properties by applying differing conditioning using our shrink tunnel simulation.

Objective:

Optimise your collation shrink film properties, including appearance and holding properties.

Test Scope:

- Holding properties

- Shrinkage

- Tensile test

- Coefficient of friction

- More

ISTA CERTIFICATION (INTERNATIONAL SAFE TRANSIT ASSOCIATION)

As an ISTA certified lab, we offer tests according to the protocol designed by ISTA. The test includes a range of simulations of transportation environments and damaging motions from distribution standards and cycles.

Objective:

Help you minimise product damage throughout your distribution and optimise your resource usage via test data for effective package design.

Test Scope:

- Environmental conditions

- Shock

- Vibration

- Compression

EUMOS 40509

This transport simulation test is per EUMOS 40509 standard commonly used in Europe. We will use our gravity force simulator to test one-way directional force emulating transportation during distribution.

Objective:

Help you determine your load stability through the performance of your packaging methods and optimise your pallet packing and stacking.

Test Scope:

- Acceleration threshold

- Deceleration threshold

- Wrapping methods

- Stacking methods

PALLETISED LOAD SECURING DYNAMIC TEST

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.