In Pursuit of Knowledge & Inspiration at ISTA’s Asia Pacific Packaging Symposium

Newton participated in the ISTA Asia Pacific Packaging Symposium 2017 in Bangkok, Thailand. Organised by the ISTA Asia Pacific Division Board and hosted by Kasetsart University Department of Packaging and Materials Technology, the symposium was held from November 1st to 3rd and attended by packaging industry players, including brand owners.

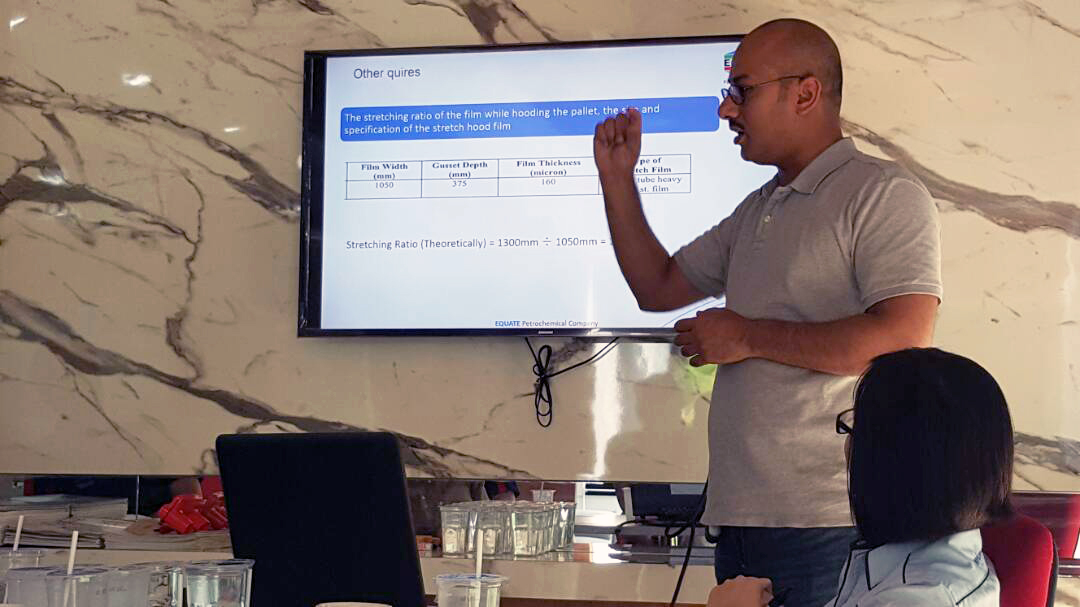

Some of the topics covered during the symposium were

- SPECIAL PROGRAM: Learn from ISTA Experts on how to Design, Develop and Test Transport Packaging and Cushioning

- Reducing Packaging Costs, Damage and Environmental Footprint

- e-Commerce packaging

- Test your packaged-products systems for safe delivery

- Measure and analyse distribution environments

- Manage supply chain and cold chain packaging

- Case studies and research updates

The trip was a fruitful journey for Newton in learning and knowledge building. We learned about design, development and testing, transport packaging and cushioning from many packaging industry experts who attended the event. The sharing and knowledge gained have provided us with valuable insights to improve our testing capabilities to serve our customers better.